Artificial intelligence set to make sugar mill process crystal clear

Published on 05 July, 2011

Turning cane syrup into sugar crystals is a surprisingly complex process, involving management of many process streams of varying compositions and crystal growth rate characteristics. A succession of concentration, seeding, boiling and centrifugal processes take place in converting sugar cane into product raw sugar.

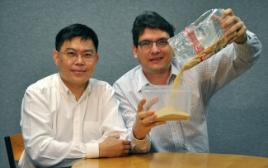

Two CQUniversity scientists are now helping to provide 'artificial intelligence' software to support decision-making by sugar mill operators, enabling the forecast of process status many hours into the future.

LINK HERE for details of the Milling Process

Dr Roland Dodd is a principal investigator and Dr Andrew Chiou is an investigator on a new research project which draws on prototyping momentum from Roland's PhD thesis and involves other specialists from QUT and RMIT. Grant partners also include the Sugar Research Institute, the Sugar Research Development Corporation and Sucrogen.

Millions of dollars are at stake, if process efficiencies can be proven in testing being arranged for a sugar mill near Ingham over the next few years.

The investigating team have won a $671,002 grant through a nationally-competitive research grant provided by the Australian Government Sugar Research and Development Corporation (SRDC) with $326,116 of direct government funding and $344,886 in-kind support.

"No more than 13 of the original 73 project proposals to SRDC, during 2009 round, were funded so there was some stiff competition," Dr Dodd said.

"The grant supports implementation of a supervisory control system for crystallisation and fugal station operations in Australian sugar mills.

"This system is based on an intelligent industrial decision support platform and industrial process models, with the grant focusing on implementation and commercialisation aspects of this technology within the sugar mill environment.

"This project aims to demonstrate the viability of the developed framework through improved sugar productivity and quality, reduction of production costs, increasing equipment utilisation and improving the decision making process undertaken by factory staff within the sugar mill crystallisation stage and fugal operational areas. Live factory trials are to demonstrate the merits of the proposed technology."

Dr Chiou says the proposed system, rather than replacing human effort, will provide parallel predictive systems for decision support by working in partnership with current operators and sugar mill systems.

Roland and Andrew bring key information systems engineering skills to the research team in mapping the entire sugar mill process to predictive computer models, leading to better scheduling and efficiencies across the board.