CQU a leader in 3-D imaging of industrial materials samples

Published on 14 June, 2007

CQU is among only a few institutions in Australia with advanced capability for 3-D imaging of industrial materials samples, thanks to an upgrade of the Process Engineering and Light Metals (PELM) Centre in Gladstone.

PELM spokesperson Professor Richard Clegg said the Centre did a lot of investigative work for industries in the region using the Scanning Electron Microscope.

Professor Richard Clegg

"Typically, maintenance engineers want to find out why a particular piece of equipment, such as a pipe or a drive shaft, has cracked or has corroded during operation," he said.

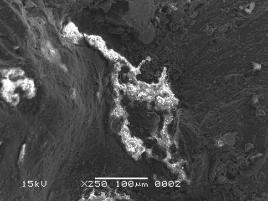

"Up until now, routine examination of the sample using the scanning electron microscope has produced pictures like the ‘before' shot below. There is information about size, phases present, but it appears two dimensional, like an aerial shot of the surface."

Professor Clegg said the PELM Centre has recently upgraded its capabilities to 3-D imaging with the acquisition of a new software suite called MEX.

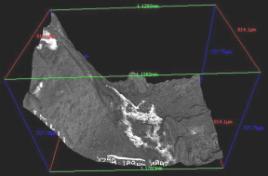

In the ‘after' shot, using this new software, the ground level detail is revealed and the aerial shot in effect becomes a three dimensional image of the surface enabling the surface texture to be seen, and enabling measurement of the actual depth of pit marks and cracks.

MEX uses the principles of stereo-imaging to reconstruct a 3-dimensional model of the surface being examined. The system works by taking at least two images of the surface. One of the images is rotated at an angle of typically 5 degrees to the other image. By measuring the geometrical changes in the surface features and by knowing the characteristics of the microscope, the software can calculate the three-dimensional parameters.

This means that a lot more information can be gathered from samples than ever before possible and provides a real breakthrough in microscopy for researchers and industries in the region.

"This capability has allowed us to turn our existing electron microscope into a 3-dimensional measuring instrument. We can use it to measure surface roughness of rails or the depths of corrosion pits simply by imaging the specimens or replicas of the specimens," said Professor Richard Clegg, acting-Director of the PELM Centre.

"This advance is computationally intensive and has only become possible with the advent of cheap computing power.

"CQU is one of the few institutions in Australia with this capability and PELM is now set up to analyse industrial materials samples to a level of detail not before available here in Central Queensland.

Professor Clegg says that this new MEX software and the Scanning Electron Microscope are now up and running and available to analyse any samples that can be imaged in the SEM.

For more information, contact Richard Clegg on 07 4970 7338 or r.clegg@cqu.edu.au or Natalia Deeva on 07 4970 7385 or n.deeva@cqu.edu.au